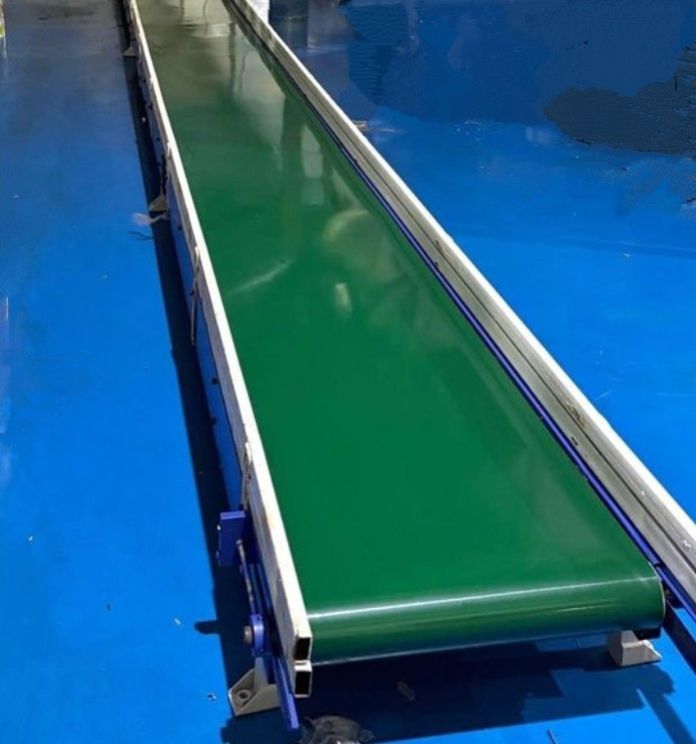

Heavy Duty Conveyor Roller

Leading Manufacturers, Wholesaler, Trader, Exporters and Retailer of Belt Conveyor System, Carrying Conveyor Roller, cone conveyor roller, Conveyor Impact return roller, Garland Idlers, Guide Roller, HDPE Conveyor Roller, Impact Conveyor Roller, Return Conveyor Roller, Self Align Training Idlers, Spiral Return Idlers and Teflon Roller from Ahmedabad.

| Business Type | Manufacturer, Exporter |

| Finishing | Polished, Unpolished, Powder Coated |

| Driven Type | Motor |

| Belt Material | PVC |

| Machine Material | Mild Steel |

| Color | Black |

| Condition | New |

| Country of Origin | India |

| Material | Metal, Steel |

| Delivery Time | 2 to 4 weeks |

A belt conveyor system can be implemented with a very economical cost per foot of the conveyor for many warehouse and industrial applications. Because it includes just one motor and a simple belt system they are quite simple. Hence they’re often one of the first productivity improvement purchases that a growing company will make. Although there are many belt conveyor types, the simplest style is known as a slider bed style. When linked together with sensors and other automation equipment a conveyor belt system can greatly enhance productivity. The weakness for them though is that generally they are only used for transport applications. This means that the belt conveyor equipment just moves the product from point A to point B. This may be sufficient, but a belt conveyor cannot typically buffer or accumulate the parts. Nor are they typically used as a working surface for production team members. As one of the leading online belt conveyor manufacturers, Ultimation can guide you through the pros and cons of the different types of belt conveyors. We’ll also help you compare if another different type of conveyor would be a better choice. WHAT ARE THE TYPES OF CONVEYOR BELT SYSTEMS? Slider Bed Belt Conveyor Roller Bed Incline Belt – Slider Incline Belt – Roller Troughed Belt Conveyor Trough Drum conveyor belt Looking for a conveyor belt for sale? These models shown below are a small sample of the variations available from our catalog. You can download the full catalog from this page or call our team for help. BELT CONVEYOR ADVANTAGES – USE THEM TO: Move simple products from one location to another Move products up or down inclines. Check with our engineers on the highest angle for your product. We generally limit the incline of a belt style system to 25 degrees Move in either continuous or indexing modes. The belt can stop and starts each time to move a product. If you place a sensor at the end of the belt, the conveyor can stop. In other cases, packages are loaded and unloaded from a continuously running belt Use when changing the speed is necessary. We can add a VFD (variable frequency drive) for speed control. This works by changing the frequency of the electrical current. A powered conveyor with a belt is a simple conveyor to adjust the speed on Moving a product around curves. Curve style systems are available to maintain the proper product orientation while a product moves around the curve DISADVANTAGES – DON’T USE THEM IF YOU NEED: Accumulating products (i.e. for a buffer). Belt style conveyors can’t allow the products to nest up against each other (“accumulate”). If you let products pile up against each other, they will get damaged. You could also have problems with them pushing product off the belt. If you need accumulation, use a roller conveyor or overhead conveyor. Accumulation means buffering. Products that won’t slide or roll off the belt. A powered belt system requires the part to ride on the belt without sliding. If you need the parts to be held while on the conveyor, there are other alternatives. Consider a slat conveyor which can be fitted with tooling to hold the product in place. As the conveyor moves along the product rides in the tooling on the slats. To use the conveyor as a working surface. Belt style conveyors are made for transport, not for production operations on them. Use a slat conveyor or roller conveyor for these type of situations. DIFFERENT TYPES OF BELT MATERIAL CHOICES General purpose belting material Rough top belt – for extra grip on inclines, declines and products that might slide Higher chemical resistance – for best protection from chemicals Cut resistant conveyor belt material – for rough or sharp items like sheet metal or bricks. The extreme heavy duty belts are very strong High temperature conveyor belt. For parts coming out of hot presses, we have belt materials available. In some cases, belt conveyors can run through lower temperature ovens. STYLES AVAILABLE IN CUSTOM CONFIGURATIONS: De

| Business Type | Manufacturer, Supplier, Trader |

| Country of Origin | India |

| Type | Solid |

| Application | Conveyor System |

| Color | Black, Grey |

| Finishing | Polished |

| Material | Metal |

Specifications of Heavy Duty Steel Conveyor Rollers

Roller Dia. (mm) 63, 89, 108, 133, 159,194, 219

No-standard Roller Dia. 76, 102, 114, 127, 140, 152 ,168, 178

Roller Shell Thickness (mm) 3, 3.5, 4, 4.5, 5.0, 6.0, 6.3

Roller Shaft Dia. (mm) 15, 20, 25, 30, 40

Roller Length (mm) 186 - 3382

Belt Width (mm) 300 - 3000

Bearings 6204, 6205, 6305, 6206, 6306, 6308

Material Steel

Standard DIN, CEMA, JIS, AS, SANS-SABS, GOST, AFNOR etc.

| Business Type | Manufacturer |

| Application | Moving Goods |

| Condition | New |

| Color | Black, Silver |

| Roller Material | Casting |

Product Description

Our expertise lies in manufacturing assortment of Conveyor Taper Roller that are used in Taper

Roller in All type Belt conveyor system. Like Ceramic , Cement , Sugar, Rise mill etc..\Our clients can avail these Rollers at highly competitive prices in market.

Features:

Effective functionality

Long service life

Defect free range

Rigid construction

Exceptional performance

Specifications:

Glass technology

330 code bearings

Special custom orders

434 code bearings

Applications:

Road Construction Plant

Mining Plant

Sugar Plant

Material Handling Plant

| Business Type | Manufacturer |

| Material | Metal, Stainless Steel, Steel |

| Finishing | Polished |

| Color | Black |

| Condition | New |

| Application | Moving Goods |

| Feature | Excellent Quality, Long Life, Scratch Proof |

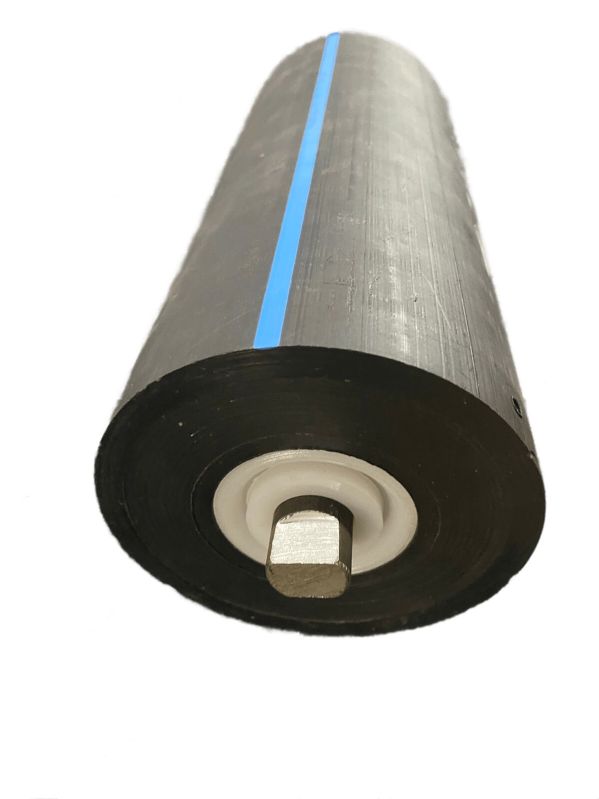

Rubber Disc Return Roller for Belt Conveyor

Belt Conveyor Rubber Disc Conveyor Return Roller is mainly used in the field of viscous material transportation. We are Rubber Disc Conveyor Return Roller manufacturer. You can get conveyor roller price from our company.

APPLICATION

Coal, mine, quarry, cement, harbor, steel, power, crusher, screen industry. Widely used in the outdoor dust is bigger, high corrosive environment, such as mines, power plants, steel making plant, stones quarry factory, cement making plant, coal washing plant, salt factories, soda, fertilizer plants, dockside/port/terminal, etc.

FEATURES

1. Rubber Disc Return rollers are covered with a series of rubber rings of adequate thickness. Highly resistant to wear by abrasion.

2. The lighter weight than conventional Impact rollers, thus a significant reduction in energy or start-up costs on conveyor drives. Seal offers a low friction coefficient. Energy Efficient bearings ensures a low power demand for conveyors.

3. Designed to operate in extreme temperatures, harsh operating conditions, and in highly corrosive chemical or coastal conditions.

4. Rubber Disc Return rollers are fitted with the same HDPE end caps and does not damage belt. Its frictional characteristics results in less build up and decreased abrasive action on conveyor belts.

Specifications of Belt Conveyor Rubber Disc Conveyor Return Roller

Roller Dia. (mm) 108,133, 159, 180

Roller Shell Dia. (mm) 60, 63, 89, 108

Roller Shell Thickness (mm) 2.0, 3.0, 3.5

Roller Shaft Dia. 15, 20, 25, 30, 40

Roller Length (mm) 406 - 2540 (Overall)

Belt Width (mm) 300 - 2200

Rubber Ring Type Rubber Ring Black (Flat Face), Rubber Conical Ring

Bearing No. 6202, 6204, 6205, 6206, 6308

Standard DIN, CEMA, JIS, AS, SANS-SABS, GOST, AFNOR etc.

| Business Type | Manufacturer, Exporter, Supplier |

| Finishing | Polished |

| Shape | Round |

| Color | Black, Green, Grey, Orange, Red |

| Condition | New |

| Application | Conveyor |

The roll garland idler is a vital component in conveyor systems, designed to provide support and guidance for the conveyor belt. The garland idlers were originally developed to improve belt conveying of large conveying capacities and large lumps.

APPLICATION

Garland idlers are often used in applications where the conveyor belt requires extra support, such as in high-capacity conveyors, overland conveyors, or situations where the conveyor belt needs to navigate complex paths. They play a crucial role in maintaining belt alignment and minimizing friction, ensuring smooth and efficient material transportation in industries such as mining, construction, agriculture, and logistics

Specifications of Garland Idlers

Suspended Idler Set Type

Belt Width

Garland Idlers (Upper and Return, 2 Rollers) 500 - 2600

Garland Idlers (Upper and Impact, 3 Rollers) 500 - 2600

Garland Idlers (Upper and Impact, 5 Rollers) 800 - 2600

Roller Materials steel or stainless steel

Standard DIN, CEMA, JIS, AS, SANS-SABS, GOST, AFNOR etc.

| Business Type | Manufacturer, Supplier |

| Country of Origin | India |

| Type | Guide Rollers |

| Feature | Durable, Easy To Fit, Fine Finished, High Strength, Optimum Quality, Smooth Function |

| Application | Industrial |

| Shape | Round |

| Roller Length (mm) | 800-1000, >1000 |

| Roller Materials | HDPE |

| Roller Diameter (meters) | 60-300mm |

| Business Type | Manufacturer, Supplier |

| Roller Diameter | 0-50 Mm |

| Country of Origin | India |

| Color | Black |

| Roller Materials | Steel And HDPE |

| Roller Length (mm) | 400-600 mm |

| Finish | Galvanized |

| Surface | Color Coated |

HDPE Rollers for Belt Conveyor

Using the on-site extrusion machinery, SKE Industries ensures the non-toxic and recycled HDPE pipes of superior quality, which have higher tensile strength and impact resistance properties.

APPLICATION

HDPE conveyor rollers are generally used in the dusty and corrosive environment such as mining industry, iron and steel, cement, smelting, power, chemistry, construction material, coal washing, foodstuff processing, port activities etc..

FEATURES

1. Non-corrosive excellent abrasion resistance.

2. 50% Lighter than steel roller, long lifespan.

3. Lower start-up costs on conveyer drives.

4. Recyclable, energy efficient, decreases vibration.

5. Lowers maintenance costs, minimizes damage to conveyer belts.

6. Non-toxic HDPE pipe.

7. Water-tight sealing arrangement.

8. Performs well in harsh weather and extreme applications.

HDPE Roller Spec.

Roller Dia. (mm) 89, 108, 133, 102, 127

HDPE Tube Thickness (mm) 9.0, 9.5, 10.5, 11.0

Inner Steel Tube Dia. (mm) 65, 80, 108, 102

Inner Steel Tube Thickness. (mm) 1.5, 2.0

Roller Shaft Dia. (mm) 20, 25

Roller Length (mm) 186 - 1632 *

Belt Width (mm) 300 - 1400

Bearings No. 6204, 6205

Standard DIN, CEMA, JIS, AS,etc.

| Business Type | Manufacturer, Supplier |

| Application | Industrial |

| Country of Origin | India |

| Color | Black |

| Material | Rubber |

| Roller Diameter | 165 mm |

| Roller Length | 3000 mm |

| Belt Width | 2500 mm |

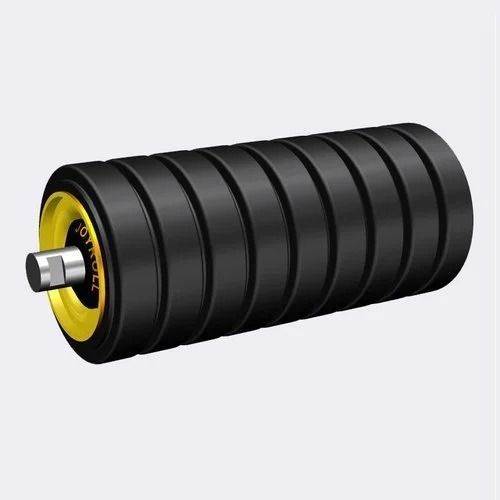

Impact roller is used in loading zone and transfer point applications. The rubber discs are assembled onto heavy duty steel roller, it can protect the belt where the lumps, weight or shape can cause damage to the belt cover from the free fall of material. The roller are standardised and designed according to international standards. Custom made rollers are available on request. Hexacon Enterprises have the capable of delivering a range of special-design rollers: water proof rollers, rollers for extreme climate conditions, conveyor roller for extreme loading, high speed conveyor rollers, low noise rollers, rollers for chemical conditions and case-hardened rollers.

SPECIFICATION:

Roller Diameter: 89, 102, 108, 114, 127, 133, 140, 152, 159, 165, 178, 194, 219mm

Roller Length: 100-2400mm.

Shaft Diameter: 20, 25, 30, 35, 40, 45, 50mm

Bearing type: 6204, 6205, 6305, 6206, 6306, 6307, 6308, 6309, 6310

Standard: DIN, CEMA, JIS, AS, SANS-SABS, GOST, AFNOR etc.

FEATURES:

1. Absorbs weight and shocks;

2. High loading capacity;

3. Highly-effective labyrinth seals protected from dust & water into the bearing;

4. Designed and manufactured for a long, trouble-free life;

5. Maintenance-free, high-quality sealed ball bearing.

APPLICATION:

Mining

Steel mill

Cement plant

Power plant

Chemical Plant

Sea Port

Storage

etc.

| Business Type | Manufacturer, Supplier |

| Country of Origin | India |

| Feature | Excellent Quality, Efficient Performance,Rust Proof,Smooth Finish |

| Application | Industrial |

| Condition | New |

| Color | Black, Blue, Grey |

| Finishing | Polished |

| Material | Metal, Stainless Steel, Steel, Mild Steel |

Return Rollers for Belt Conveyor

We are conveyor return roller manufacturer and provide flat return roller, self-aligning return roller, v return roller, and friction return roller for sale. You can contact us for quotation now.

APPLICATION

Belt conveyor return rollers are used to support the belt as it cycles around to be loaded again. Standard Return Rollers are available with a steel roll and 2 drop brackets. Return roller support the belt to prevent stretching, sagging, and failure.

Specification of Conveyor Return Rollers

Type Belt Width (mm)

Flat Return Roller (1 roller) 300 - 2000

V Return Roller (2 rollers) 650 - 2200

Self-aling Carry Roller (1 rollers) 400 - 1600

Self-aling Carry Roller (2 rollers) 400 - 2200

Standard DIN, CEMA, JIS, AS, SANS-SABS, GOST, AFNOR etc.

| Business Type | Manufacturer, Exporter, Supplier |

| Finishing | Non Polished, Polished |

| Shape | Round |

| Color | Black, Green, Grey, Orange, Red |

| Condition | New |

| Application | Conveyor |

Training Idlers | Self Aligning Idlers for Belt Conveyor

We are self aligning idler manufacturer. Our self-aligning idlers are designed to automatically adjust and maintain the alignment of the conveyor belt. We offer training carrying idler and return idler for sale.

APPLICATION

Self-aligning idlers are specifically designed to address issues of conveyor belt misalignment. Self-aligning idlers typically have a unique design that allows the idler to pivot or tilt in response to any deviation in the belt's alignment. Self Aligning Conveyor Idler (Training Idlers) can be used in tracking of both return and load-carrying side and find use in reversible conveyor belts, high-load conveyor belts slow moving conveyor belts. You can use them in industries of Mining, Steel mill, Cement plant, Power plant, Chemical Plant, Sea Port, Storage, etc.

Specification of Conveyor Training Idlers

Trough Idler Type Belt Width (mm)

Self-aling Trough Idler (3 rollers) 400 - 2200

Trough Friction Idler, Self-aling Idler (3 rollers) 400 - 1400

Trough Tapered Idler, Self-aling Idler (3 rollers) 800 - 2000

Return Training Idler (1 roller) 400 - 1600

Return Training Idler (2 roller) 400 - 2200

Standard DIN, CEMA, JIS, AS, SANS-SABS, GOST, AFNOR etc.

| Business Type | Manufacturer, Exporter, Supplier |

| Finishing | Non Polished, Polished |

| Shape | Round |

| Color | Green, Orange, Red |

| Condition | New |

| Application | Conveyor |

Spiral Return Idlers for Belt Conveyor

This Belt Conveyor Spiral Idler, also called screw conveyor idler and screw roller, is designed for conveying sticky materials and it has self-cleaning ability to ensure high working efficiency.

APPLICATION

The Conveyor Spiral Idlers are used on the return side of the belt as belt cleaner. Spiral steel welded on the spiral roller act as a screw and pushes the build-up material on the center to the edge of the belt, return roller. Our products are widely used in thermal power generation, harbors, cement plants, metallurgy and as well as the light duty conveying devices for industries.

FEATURES

Preventing material buildup, Self-cleaning, non-stick surface

Specially advantageous with sticky materials on return side;

Highly-effective labyrinth seals protected from dust & water into the bearing;

Designed and manufactured for a long, trouble-free life;

Maintenance-free, high-quality sealed ball bearing.

Specifications of Spiral Conveyor Return Idler

Standard Diameter (mm) 108-219

Length scope (mm) 900-3350

Idler's Shell Wall Thickness (mm) 3.0-6.0 (customizable)

Standard DIN, CEMA, JIS, AS, SANS-SABS, GOST, AFNOR etc.

| Business Type | Manufacturer |

| Condition | New |

Teflon has emerged as one of the most sought-after materials in manufacturing industries considering its unique properties, features, and application. As a result, Teflon-coated rollers manufacturing industries are showing a consistent growth trajectory.

In this blog, we are going to highlight Teflon pressure rollers, their unique features, applications, and industries drawing benefits from the Teflon-coated rollers by Teflon roller manufacturers.

Why do manufacturing industries use Teflon-coated rollers? What is so special about the roller? These and many similar questions will be answered in this blog. According to industry experts, Teflon is widely acclaimed for various unique features and properties, making it ideal for manufacturing companies.

In the ensuing sections, we are going to highlight many important things about the industry-centric product.

From the basics, let's now shift our focus toward the unique properties of the Teflon-coated rollers.

Unique properties of Teflon pressure roller

A quality-driven Teflon pressure roller by Teflon roller manufacturers is widely admired for depicting a variety of unique features. These include:

Resistant to wear and tear

Returns to its original shape, if distorted during application

Resistant to chemicals

Resistant to scratching and bumping

Sturdy Teflon coating

High tensile strength

High coefficient of friction

Sturdy design

Consistency in performance

In addition, it has the quality to speedily compensate for small changes that occur in the machine’s precision. As a result, the durability of the product gets increased. At the same time, the Teflon pressure roller requires less maintenance, making it ideal for the manufacturing process. For more information, you can get in touch with a few famous Teflon roller manufacturers in Ahmedabad, India.

Application

Over the years, a wide range of manufacturing industries has shown interest in integrating Teflon-coated rollers in their manufacturing process considering its features and significance. The quality-driven product is used in the following applications:

For hot flue

Dying

In addition, the product has found usage in many other applications. For more information, we suggest you get in touch with a few popular Teflon roller manufacturers. Their product knowledge and expertise will help you expand your knowledge about the terrific product.

From the application section, let’s now shift our focus towards the industries benefitting from the Teflon pressure roller.

Industry

Teflon coating brings along with it a variety of features and properties, making it useful to many industries. For instance, resistant to corrosive chemicals, insulation from electricity, doesn’t absorb water, can withstand extreme heat and cold and creates little friction among others. Subsequently, Teflon-coated rollers have found application in the following industries:

Packaging

Textile

Paper

Plywood

Many of your queries regarding Teflon-coated rollers have been addressed in this blog. With the advent of modern technology Teflon roller manufacturers have been empowered to roll out an innovative range of rollers.